Semiconductors

Suppliers and semiconductors

Sourcing the right components plays a key role in production of a good and successful product. Especially in the field of electronics, high-quality components ensure durability and process reliability. With supply chain disruptions making it difficult for electronics companies to source genuine components, our top priority as electronics sourcing professionals is to connect with a network of trusted suppliers.

Suppliers in all industries keep making promises. This is no different for suppliers of electronic components. OEM24 helps companies source the highest quality semiconductor components and industrial automation solutions with cost-effective supply chain solutions.

Always verify promises!

Demand for electronic parts In the era of rapidly changing technology and shorter product life cycle will make some electronic parts more and more difficult to obtain. However, proper planning will help your business handle this with ease. The best way is to build strong partnerships with suppliers who are experts in providing these hard-to-find components.

At OEM24, we offer a wide variety of electronic components, from the hard-to-find to the latest, yet hard-to-find components. We offer fastest possible delivery with the best customer service and high quality of goods considering the costs.

Whether you are looking for a semiconductor or a new electrical part, we can help you get it easily.

we offer a wide range of electronic components,

from hard to find to the newest,

yet still hard to come by.

Companies whose solutions we can offer

Contact us today!

We will reply as soon as possible!

Semiconductors in a larger scale

The current global semiconductor shortage is caused by a combination of high demand and low supply. The main reason for the increasing demand could be that nowadays we are using more advanced technology than ever before. The shortage of components has already caused problems for many industries. The automotive industry was particularly hard hit, but the lack of access to semiconductors has also caused supply bottlenecks in the consumer electronics industry.

Due to the fall in car sales, demand was reduced and as a result semiconductor production also fell. However, demand for consumer goods increased rapidly, necessitating the conversion of semiconductor production lines from auto chip production to more expensive processors.

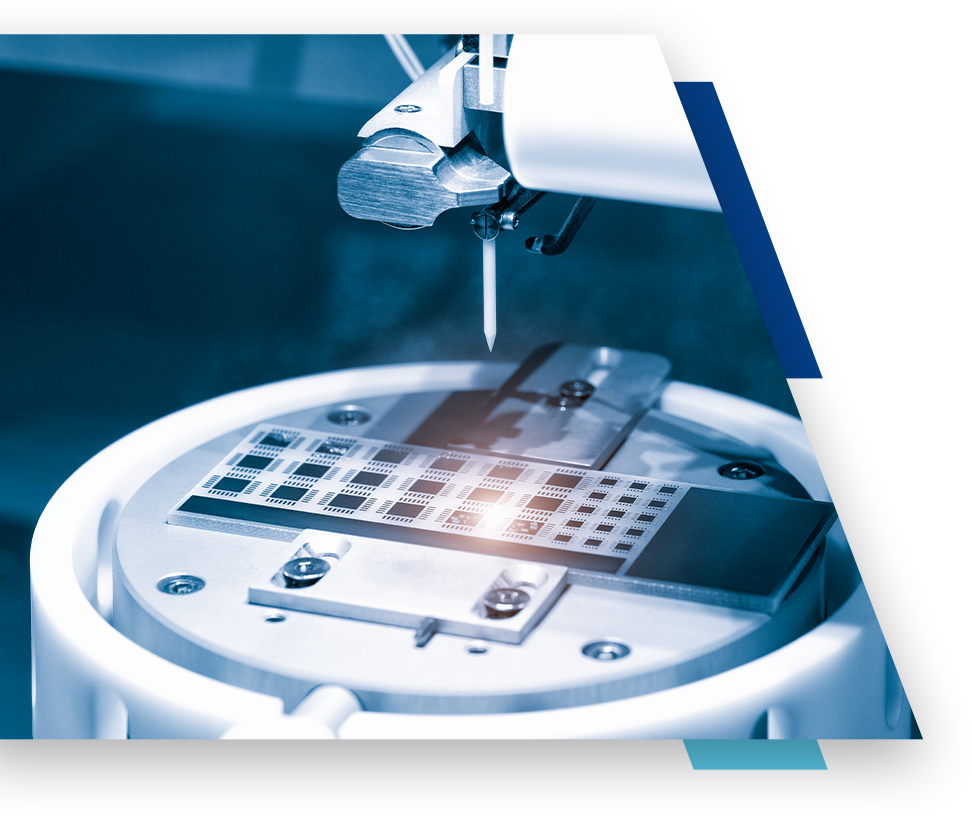

Designing and manufacturing semiconductor chips is one of the most advanced processes. It covers the area of very delicate production processes and can last up to three months or even longer. The next steps are electroplating, series of measurements, inspection, tests, etc. In addition, each semiconductor chip goes through all these steps many times until it is sufficiently powerful and ready for use. These are the main reasons why semiconductor chip manufacturing is complicated and the whole process takes so long. The increased lead time meant that increasing production capacity alone could not bridge the gap between supply and demand.

Many people worried about the lack of cutting-edge chips, fortunately, TSMC (in Taiwan), Intel Corp. (in the US) and GlobalFoundries have made huge investments and spent billions of dollars upgrading facilities and building new production lines. Semiconductors are a key element that is used at many levels and in various industries. The development of each and every one of them is undoubtedly related to the groundbreaking quick access to advanced components in today’s rapidly changing world. It is undoubtedly clear that when governments are currently in crisis management mode around the world, semiconductors and stable access to them can be described as critical infrastructure on a global scale.

According to Intel CEO Patrick Gelsinger, the shortage could continue for two more years. On the other hand, the Chinese Automobile Industry Association has announced that the worst global auto chip crisis is over.

Beyond responsible planning, there are some additional things companies can do to prepare for a global semiconductor shortage. The first thing you need to do is find a good semiconductor distributor like OEM24 and keep in touch with them. This ensures access to semiconductors even if a supplier has problems. Another thing companies can do is stock up on spare parts. This will help you survive short term supply chain disruptions.

The global semiconductor shortage is a serious problem affecting many industries. By diversifying their supplier base and increasing spare parts inventories, companies can reduce the risk of business interruption.